YU Research Team Develops New Technology for 'Metal-Ceramic Connection' N

No.88949- Writer pr

- Date : 2017.03.31 10:26

- Views : 8608

School of Materials Science and Engineering Professor Ko Young-gun's team applies 'plasma electrolysis oxidation technologies' using the principles of volcanic explosions

Succeeded in controlling plasma intensity, ceramic coating layer 'surface property improved significantly'

Published in the recent online edition of the world acclaimed academic journal 'Scientific Report'

[March 21, 2017]

Succeeded in controlling plasma intensity, ceramic coating layer 'surface property improved significantly'

Published in the recent online edition of the world acclaimed academic journal 'Scientific Report'

[March 21, 2017]

<YU School of Materials Science and Engineering research team developed a new technology that connects metals with ceramics.>

(left to right: Muhamad Prisla Kamil, Professor Ko Young-gun)

(left to right: Muhamad Prisla Kamil, Professor Ko Young-gun)

The YU School of Materials Science and Engineering Professor Ko Young-gun's research team attracted attention from academic circles by developing a new technology that connects metals with ceramics.

Recently, Professor Ko's research team announced the research results for 'Metal-Ceramic Connecting Coating Technologies using Soft Plasma Arc Technologies'. Plasma separates electrons with negative electric charges and ion with electrons and positive electric charges at extremely high temperatures, and is called a 'fourth state of matter' that is not solid, liquid or gas. Such plasma is applied in various areas from extremely high temperature nuclear fusion at billions of degrees to semiconductor processes and new material combination as well as plasma discharge.

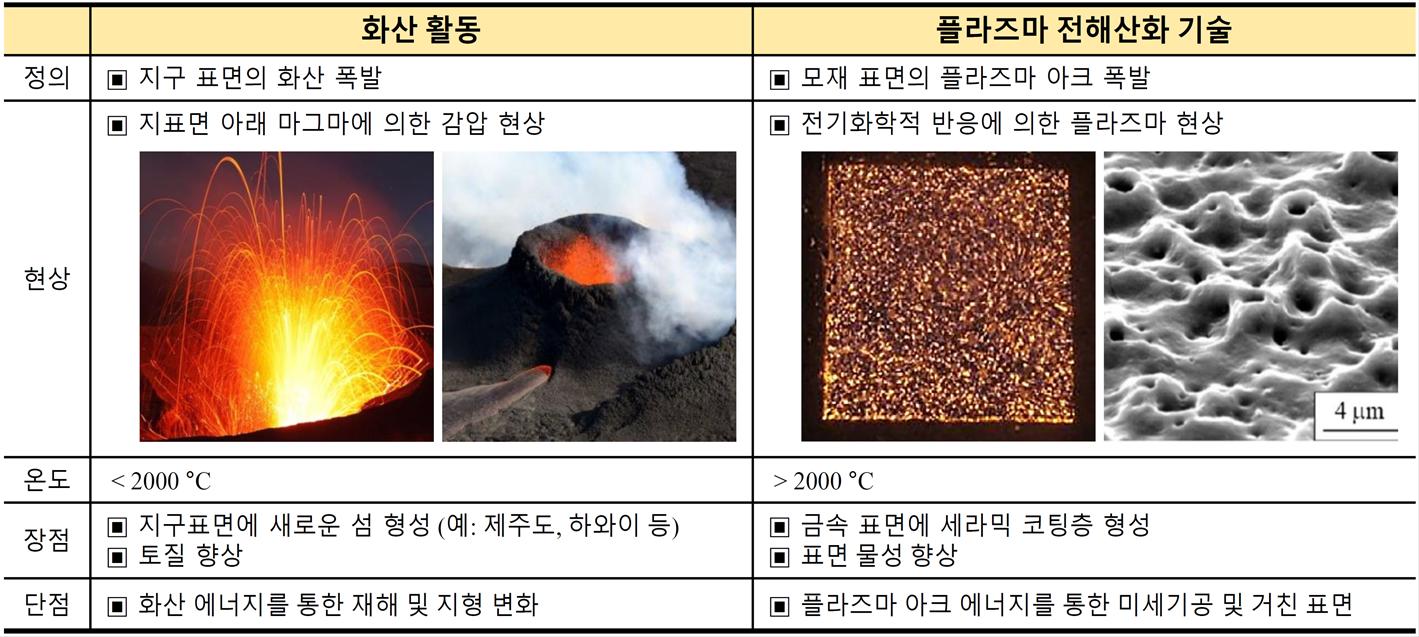

In this study, the research team applied 'PEO (Plasma Electrolytic Oxidation)' using plasma. Professor Ko said, "Plasma electrolysis oxidation technologies are very similar to the mechanism of natural volcanic explosions. Just as new islands such as Jeju-do and Hawaii are formed on the surface through extreme volcanic activities, it is possible to create a ceramic layer on a metal surface through high energy plasma." He added, "By developing a new technology that can control plasma intensity, it was possible to form a ceramic layer on a metal surface, while significantly improving surface properties by utilizing the unique features of ceramics." <Figure 1>

In this study, the research team applied 'PEO (Plasma Electrolytic Oxidation)' using plasma. Professor Ko said, "Plasma electrolysis oxidation technologies are very similar to the mechanism of natural volcanic explosions. Just as new islands such as Jeju-do and Hawaii are formed on the surface through extreme volcanic activities, it is possible to create a ceramic layer on a metal surface through high energy plasma." He added, "By developing a new technology that can control plasma intensity, it was possible to form a ceramic layer on a metal surface, while significantly improving surface properties by utilizing the unique features of ceramics." <Figure 1>

<Figure 1. Comparison of Volcanic Activities and Plasma Electrolysis Oxidation Technologies>

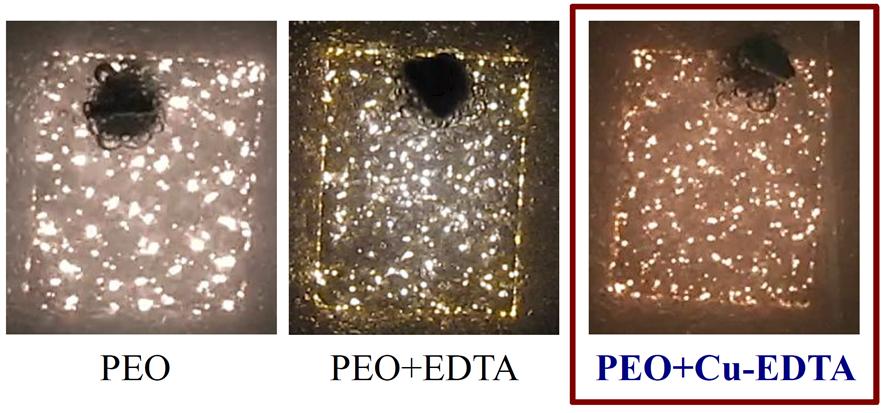

In particular, Professor Ko's research team utilized ethylenediaminetetraacetic acid (EDTA) and copper-EDTA organic compounds to successfully control 'soft plasma-arc'. Defects and pores that occur due to <Figure 2> were considerably decreased.

<Figure 2. Soft plasma arc controlled by organic compounds>

The research results were published in the latest (March 10) online version of <Scientific Reports> (impact factor (IF) 5.228), which is the sister journal of Nature.

Professor Ko said, "In the case of actual volcanic activities, it is not possible for humans to adjust the intensity of volcanic explosions, but in the case of plasma arcs, we have finally made it possible through this research for humans to control it." He added, "The results of this study is a groundbreaking electro-chemical technology that can improve the anti-oxidizing, anti-abrasion, and bio properties of nonferrous metals such as magnesium, aluminum and titanium in the future. In particular, the fields of application are unlimited depending on organic-inorganic combinations, and so it can be utilized to create new industries related to new material surface control technologies such as mobile devices, automobiles and implants.

Meanwhile, this study was carried out with the support of the Ministry of Trade, Industry and Energy, and Muahamad Prisla Kamil (25, YU Graduate School of Materials Science and Engineering, 5th terms in Master's and PhD combined program) from Indonesia participated as the first author, while advisor Ko Young-gun participated as a correspondence author.

Meanwhile, this study was carried out with the support of the Ministry of Trade, Industry and Energy, and Muahamad Prisla Kamil (25, YU Graduate School of Materials Science and Engineering, 5th terms in Master's and PhD combined program) from Indonesia participated as the first author, while advisor Ko Young-gun participated as a correspondence author.